3 ECS Key Application Areas

3.3

Digital Industry

“Digital Industry” chapter intends to highlight the evolution of traditional industry

through the introduction of cutting-edge digital technologies in production,

management and distribution processes.

These technologies include the Internet of Things (IoT), artificial intelligence

(AI), data analysis, co-robotics, 3D printing and all digital innovations that can

be usefully adopted in industry (advancements on sensing, powering, communications,

computing, etc… )

Digital Industry is characterized by the increasing integration of the physical world with the digital one by means of the data exploitation provided by an ever more pervasive digitalization. The digitalization allows to move under the same objective heterogeneous topics inherent to the different steps on the lifecycle of the products -like as from the design to the efficiency and the maintenance of the production machineries- involving all aspects of industry and business activities, including workers and the working environment.

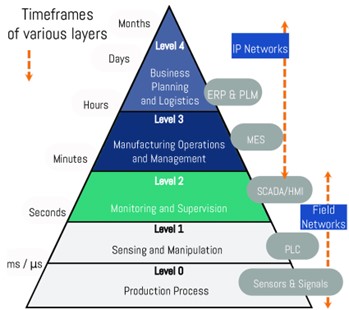

To be able to manage everything in a machine, factory or company network, industries have divided the necessary technologies into levels or technology stacks. In these levels or stacks, sensors and actuators are closest to processing materials or handling items, and therefore seen as the lowest in the hierarchy in the Edge-to-Cloud Continuum. Moving up the levels, you find super-sets and/or System of Systems and/or interconnected IoTs like devices, unit processes, production or manufacturing lines, operations control, company or enterprise business processes, and an increasing number of machines, lines, company boarders, as manufacturing has become more networked, complex, dynamic and global.

The Industry 4.0 changes to the mode of operation have a profound impact on how are managed and operated the factories, supply chains, construction zones and processes. Powerful networked digital tools are needed to achieve the necessary Situational Awareness and control of autonomous vehicles, robots and processes at various autonomy levels allowing the ever more pervasive Industry 5.0 approach. The technological tools that are part of the symbiotic decentralized Web 5.0 concept can encompass such complex non-hierarchical environments and allows control of user data.

The European Industry 4.0 and 5.0 revolution needs an open-source-based, stable and extensible semantic Internet to overcome user interface, networking and communication challenges. The Internet with smart agents is an overarching concept containing multiple technologies, such as Industrial Internet of Things, Artificial Intelligence (AI), Advanced Data Analytics, Augmented and Virtual Reality (AR /VR). The Internet with Industrial Metaverse (Digital Twins) can be seen as an expanding set of interconnected virtual and augmented worlds, accessible from AR/VR head mounted displays, desktop computers and even mobile phones. The entities that are present in the Industrial Metaverse may be humans, devices and autonomous physical and virtual machines such as Digital Twins and AI agents. The digital transformation of the manufacturing processes, creation of the software tools, data-driven and AI-supported decision making, harmonization of human-technology relationship, is enabling upcoming human-robot coworking toward Industry 5.0.

This SRIA addresses the digitalisation of the major European industrial sectors promoting the European sovereignty in the internal manufacturing ecosystem together with future sustainability and greener industrial processes and artefacts. These include discrete manufacturing (e.g. manufacturing of automobiles, trains, airplanes, satellites, white goods, furniture, toys and smartphones), process industries (e.g. chemical, petrochemical, food, pharmaceuticals, pulp and paper, and steel), provisioning, production services, machinery and connected machines, UAVs and robots. Emphasis is also given to any type of factories, productive plants and operating sites, value chains, supply chains and lifecycles, new materials for structures and electronic components.

Digitalisation is as a key enabler for the future success of European industry. This Chapter will address the potential for the development of topics such as responsive, smart and sustainable production, Artificial Intelligence (AI) in digital industry, industrial services, digital twins and autonomous systems. As discussed at the end of the Chapter, nearly all of the topics in the Technology chapters of the SRIA are of vital importance to industrial applications. These include standardisation, engineering tools, cybersecurity and digital platforms. To digitise European industry and enlarging and embedding the related e-supply chains, potentially all enabling technologies will need to be employed to realise the required competitive edge, and of course a focus on digital industry would not be complete without the exploitation of enabling technologies in the industry field.

Today, the digital landscape remains fractured, with significant challenges in areas such as standardisation, interoperability, and translating research to real commercial impact. These challenges must be met effectively if we are to achieve a strong, greener, resilient, responsive European economy, where sustainable, human-centric solutions help Europe achieve strategic autonomy into the future, as also well outlined in the Draghi Report1 “EU competitiveness: Looking ahead” and in the more sectorial WMF Report 2024 called “New Perspectives for the Future of Manufacturing: Outlook 2030”2.

The recent “2030 Digital Decade” Annex I3 of the Shaping Europe’s Digital Future4 Commission Report highlights the urgent need for the EU to prioritise action in areas that foster innovation and growth, improve productivity, and mitigate disruptions – in particular in the areas of digital technologies and digital skills.

Europe needs an industry that becomes greener, circular and more digital while remaining competitive on the global stage. The twin ecological and digital transitions will affect every part of our economy, society and industry. They will require new technologies, with investment and innovation to match. They will create new products, services, markets and business models. They will shape new types of jobs that do not yet exist which need skills that we do not yet have. And they will entail a shift from linear production to a circular economy.

The digital sector will also contribute to the European Green Deal, both as a source of clean technology solutions and by reducing its own carbon footprint. Scalability is key in a digitalised economy, so strengthening the digital single market will underpin Europe’s transition. Europe must also speed up investment in research and the deployment of technology in areas such as AI, 5G/6G, data and metadata management. 5G/6G private networks will become into the industry and at the same time hybrid clouds will enable networks that are sharing content and resources seamlessly. This will be required by Web 4.0 smart services and things: goal oriented intelligent connection of semantic resources. Connectivity will expand between systems and people. Personnel at the mill level will be more aware and artificial knowledge from the cloud will be nearby all the devices, sensors and processes to the human. This can be made more accurate, for example, with precision time protocol (PTP) support on hardware level (industrial devices at least) to get better indoor location (by means communication improved capabilities, like as Bluetooth Low Energy (BLE), Ultra Wide Band (UWB), and advancements in sensors, like as time of flight).

European factories and machines already have a high level of automation and digitisation. Many of the leading end-user companies are European based, and Europe also has a number of significant system and machine building, engineering and contracting companies that have a competitive edge in automation and digitisation. The business environment is changing. Through specialisation in new or niche end products, production is becoming more demand-driven and agile, while production is increasingly geographically distributed enlarging its supply chain. In addition, the outsourcing of auxiliary business functions such as condition monitoring and maintenance is gaining in popularity, leading to highly networked businesses. There are many opportunities for energy, waste, water, material, recycling optimisation, etc., over the value chains and across company boundaries. Such advantages can only be realised by having a significant increase in digitisation and embedding functions and intelligence within the production physical layer.

This transition should include the adoption of applications that do not require to be kept internal or confidential, as solutions based on web/cloud services allows for the mediation of key factors such as their use by non-AI professionals, and off-line development of advanced criteria models and inferential engines through the expertise of specialised centres.

The exploitation of AI for core business functions generally requires a complete rethinking of data management and their use and tracking inside the supply chain. Instead, the implementation of a System of System (SoS) framework enables the data to be to capitalised on through appropriate actions, in which analysis and analytical tools usually reach their limits. Interaction between systems will be more direct (knowing neural nets). This will require more standardized interfaces that will enable adaptive connectivity with secured access rights (part of information will remain always hidden).

Industrial Metaverse, based on digital twins, will speed up training of employees, and furthermore, facilitate building required trust to use intelligent agents. It will enable virtual simulations before actual building physical system and speed up research and innovation cycles It can be used to help field workers with AR/VR. Even product design collaboration around the world will come possible. Virtual designs will enable building physical products and vice versa: adding digital assets from physical items.

The actual value chain will come from existing installations, as it is unusual for new factories to be built. As new, fast and secure communication protocols will provide easy connectivity and interoperability across systems; this will enable the potential for extensive integration. Easy access to a secure internal network will provide all existing information to users at anytime and anywhere within the plant. Moreover, new interesting features could be accessed through cloud or edge-based computing systems. However, this will require new hardware infrastructure to be added to the plant, along with greater processing power to handle larger amounts of data.

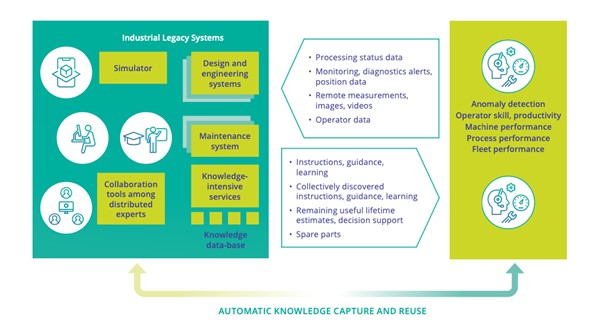

Digital infrastructure and micro services will help evolve business models towards selling added value as a service. Investment in projects will create networks between vendors and providers. In modern business- to-business (B2B) relationships, ongoing R&D and industrial pilots will aim to deliver a range of after-sales services to end customers. Typically, such services will include condition monitoring, operations support, spare parts and maintenance services, help desks, troubleshooting and operator guidance, performance reporting, as well as the increasingly required advanced big data analytics, prognostics-based decision support, and management information systems.

Industrial services often represent 50% or more of industrial business volume, and this share is steadily growing. The share of services is generally higher in high-income countries than in low-income countries. The importance of service businesses in the future is obvious, since they also enable sustained revenue after the traditional product sales, with the service business being typically many times more profitable than the actual product sale itself.

Each Major Challenge (MC) has a focus on specific topic, but we have to highlight how all digital industry MCs are characterized by a high grade of interaction among them, in which each MC takes advantages on improvements of topic in another MC. Artificial intelligence, robotics, digital twins, augmented reality, etc., appear together as connected tools to improve industry in every possible part of its domain.

On Digital Industry domain, six Major Challenges have been identified:

-

Major Challenge 1: Responsive and smart production. Focusing on the Efficiency

-

Major Challenge 2: Sustainable production. Focusing on the Planet

-

Major Challenge 3: Artificial Intelligence in digital industry. Focusing on the Smartness

-

Major Challenge 4: Industrial service business, lifecycles, remote operations and teleoperation. Focusing on the Resilience of Supply Chains

-

Major Challenge 5: Digital twins, mixed or augmented reality, telepresence. Focusing on the Digitalization

-

Major Challenge 6: Autonomous systems, collaborative robotics. Focusing on the Autonomous Production

3.3.4.1 Major Challenge 1: Responsive and smart production

Responsiveness, flexibility and smartness is currently considered inside the European productive landscape based on pre-Industry 4.0 automation technology. At the same time, in addition to the critical situations to be handled, European Industry must be much more responsive to any changes that may occur, not only from a scientific and technological point of view.

Today’s automation solutions are not inherently flexible by design.

Adaptive and self-learning systems principles must be applied to automation solutions, enabling the automation system and solution flexibility, responsiveness and smartness.

Many European initiatives and reports cover this topic:

-

“Align Act Accelerate” Report5 prepared by European Factories of the Future Research Association (EFFRA6) Expert Panel: a proposal of comprehensive reform of the Eu Research & Innovation Funding.

-

SMART-EUREKA7 mission-vision to boost the competitiveness, growth and attractiveness of the European discrete manufacturing industries through the promotion of R&D&I in an open community of industrial organisations.

-

ManuFuture8 claims that “the European manufacturing system in 2030 must be resilient and adaptive to cope with a rapidly changing and unpredictable environment, overcome disruptions and adapt to meet the changing market needs”. In their 2020 report9, the World Manufacturing Foundation calls to “leverage on AI to detect and respond to disruptions in supply networks”.

The main benefits of a more responsive and resilient production are:

-

Ability to forecast the evolution of the demand-offer-competition ecosystems

-

Capability to rapidly change production and provisioning.

-

Efficiency to become profitable with high-mix, low-volume production.

-

Capacity to operate, even with decreased operational capability.

-

Enable rapid concrete innovation, not exclusively via rapid integration and product evolution but also re-engineering the overall process and components production.

-

Limit deterioration in performance, reliability, maintainability and interoperability when plants face disturbances.

Chips JU will play a lead role in this evolution to more responsive, robust and resilient factories. From sensors integrated in wearables and prosthetics, to SOS that enable self-healing and self-reconfiguration, responsive and resilient manufacturing has always been an important challenge.

AI will also play a key role in increasing the flexibility of manufacturing systems. One example is AI applied to real-time scheduling that allows a production process to flex around rush orders and disturbances in the line or supply chain. However, while the current trend of deep learning is opening up limitless possibilities in some areas, there is a need to apply other AI approaches that are more explainable, more aware of the environment and the task at hand.

The still suffering tail effect of Covid-19 and the running wars in Ukraine and Gaza with the worldwide impacts expected for the future years has highlighted many of the reasons why a flexible factory needs to adapt better in times of change to be a more useful part of the European response to such crises by:

-

Modifying production based on medical needs and exogenous inputs.

-

Scheduling production with less human resources and social distancing constraints.

-

Empowering agile working and telepresence.

-

Adapting to changes in the supply chain, promoting European independence.

-

Developing capacity for in-kind, or inside a shorter supply chain for the production of components that usually come from the worldwide market-based supply chain.

-

Developing capacity for redesign and re-engineering, due to lack of raw materials and electronic components.

Although automation and digitisation are the building blocks for building a flexible, resilient manufacturing industry, the importance of a well-trained and agile workforce cannot be underestimated. Workforce agility and flexibility, achieved, for instance, through cross-skilling, empowered by smart technologies like AR/VR or assisting chatbots, make humans indispensable in any production process.

In terms of standardisation, standards are a significant and necessary part of all industrial applications. The modern digitalisation of industry could not exist without standards, as without standards interoperability would not be possible. They enable extensive industrial projects while ensuring quality, safety and reliability. Many engineering methods are standardised, and provide textbook consistency across professional engineering. However, standards must also be supported by the relevant engineering tools, etc., as those required for design or development are different from those required at the operation stage.

-

Robust optimal production, scalable first-time-right production: future manufacturing plants should become more robust in the sense they can continue production even when facing a disturbance. This will require advances in, for example, self-healing and redundant automation systems, first-time-right, zero-defect manufacturing, and predictive maintenance empowering very adaptable production.

-

Mass customisation and personalised manufacturing, customer-driven manufacturing: progress in recent years towards lot-size-one manufacturing and personalised product design will continue to grow in the next few years: IoT sensors will self-correct for disturbances, real-time warehouse connectivity will allow to optimise the shop-floor, edge devices will perform predictive analytics. All of these advances will allow greater flexibility.

-

Resilient and adaptive production, including the shortening of supply chains and modular and flexible factories: Resilience is a critical property for systems that can absorb internal and/or external stresses and adjust their functional organisation and performance to maintain even with a reduced productivity the necessary operations. A resilient factory will continue to operate without any breaks to achieve its objectives under varying conditions and with the ability to overcome that stress to return to ordinary condition of functionality and productivity.

-

Cognitive production: This involves deploying both natural and artificial cognition alongside IoT devices and data analytics to enable new analytics and learning that can enable responsive and sustainable adaptable production. For example, real-time monitoring against lifecycle assessment (LCA) criteria can be facilitated by the implementation of AI. More generally, it is important for cognitive production to support the emergence of simplicity rather than the combinatorial growth of complexity when complex cyber-systems are combined with complex physical systems.

-

Manufacturing as a service: Technological advances have the potential to expand the geographical distribution of manufacturing and facilitate manufacturing as a service, MaaS (a well- known example is 3D printing). The trend to move part of labour-intensive production into high value manufacturing exploits MaaS, allowing to outsource parts of the production chain, replacing the need to have dedicated lines and even the whole factory (factory less goods). Another interesting opportunity for MaaS is moveable factories, which circumvent the need for new industrial infrastructure. The scope for moveable factories is enhanced by the range of manufacturing machines and power sources that are becoming increasingly small and light enough to fit into trucks, trailers, carry cases, etc. MaaS empower the dynamic aspects of outsourcing, provisioning, making the supply chain ecosystem more resilient.

-

Embedded/Edge/Cloud architectures: Nowadays system architectures mainly consist of three layers of computing devices. Embedded computing reside very close or attached to the machinery or process. Near Computing devices are often called edge computers, routers, or local servers. Near computer nodes are powerful computers themselves and communicate both to the embedded computing cards and to the cloud via internet. A special boost in the picture comes from the 5G technology. There, the 5G communication technology takes care of the edge-to-cloud and edge-to-edge communication which will be faster than anything before. Workload and services are moved from the centralised data centres (core network) ever more to the proximity, benefiting mainly latency which is crucial for time critical application and services.

-

Standardisation: Due to the ongoing legacies of the many existing standards and their installed base (number of units of a product or service that are actually in use), focus should be on bridging the systems of the various standards. This should involve developing semantic technologies to master these diverse and numerous standards, including software or platforms that enable effective connectivity at a high application level, as well as respective digital testing, development environments and licencing. This is key to ensure there is wide acceptance and support of software vendors, engineering offices and end-users.

3.3.4.2 Major Challenge 2: Sustainable production

This Major challenge focuses on how Industry 4.0 should address the future regulation or market requirements emerging from the European Green Deal and zero-carbon (or below carbon-neutral) operations.

Nearly 200 countries have committed to the Paris Agreement on climate change to limit global warming to below 2ºC. Any update about new challenges and activities are regularly published by the EU Parliament10. The rapid transformation of all sectors is therefore required. In fact, many European countries have set even more ambitious targets, and Chips JU could have a great bearing in reducing environmental impact through sustainable manufacturing, including energy- and resource-efficiency and by applying circular economy strategies (eco-design, repair, re-use, refurbishment, remanufacture, recycle, waste prevention, waste recycling, etc).

There are some so-called rare earth metals to save, and any kind of careless materials usage can be proven uneconomical and risk to the environment. The vision of Sustainable Process Industry through Resource and Energy Efficiency (SPIRE) categorises the high-level goals discussed above into more practical action, as follows.

-

Use energy and resources more efficiently within the existing installed base of industrial processes. Reduce or prevent waste.

-

Re-use waste streams and energy within and between different sectors, including recovery, recycling and the re-use of post-consumer waste.

-

Replace current feedstock (raw material to supply or fuel a machine or industrial process) by integrating novel and renewable feedstock (such as bio-based) to reduce fossil, feedstock and mineral raw material dependency while reducing the CO2 footprint of processes or increasing the efficiency of primary feedstock. Replace current inefficient processes for more energy consumption reduction.

-

Resource-efficient processes when sustainability analysis confirms the benefits.

-

Reinvent materials and products to achieve a significantly increased impact on resource and energy efficiency over the value chain.

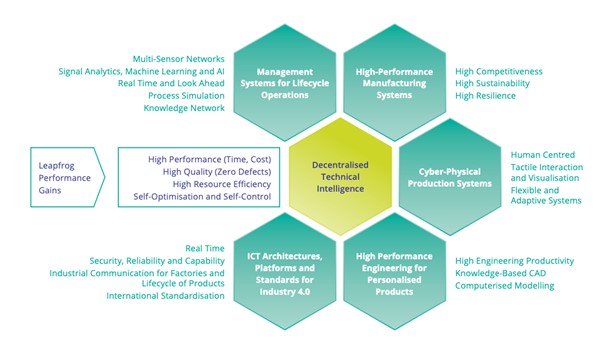

ManuFUTURE Vision 2030 combines these objectives as shown in Figure 3.3.1

A new upcoming EU co-programmed partnership called Innovative Advanced Materials for Europe (IAM4EU) will be supported by the IAM-I12 (the Innovative Advanced Material Initiative) association, which already released a template for collecting inputs for its SRIA13. This materials value chain initiative is of paramount importance for the EU manufacturing Industry and will have a great impact also in Digitalization and Semiconductor Design & Production.

-

Monitoring flows of energy, materials, waste and Lifecycle assessment: It is already commonplace in many industry sectors (food, medicine, etc) that material and energy streams need to be fully traced back to their starting point. As more and more products, raw materials, etc, become critical, this implementation strategy must be expanded. Flows need to be monitored. Sustainable manufacturing needs comprehensive environmental data and other measurements that may have been in place when the relevant manufacturing or production was initiated. On the other hand, this is a very typical application for many types of IoT sensor and systems that can be informed by careful “Life Cycle Assessment” (LCA). LCA is a prerequisite for holistic environmental evaluation, and it is a simple but systematic method, that requires a mixed combination of extensive and comprehensive models and data.

-

Virtual AI assistants: Discharges or losses mostly happen when production does not occur as planned, due to mistakes, the bad condition of machinery, unskilled operation, and so on. Human factors cause most of the variation in the running of continuous processes. There should therefore be a focus on how to implement an AI-supported assistant to help operators by providing advice and preventing less than optimal changes and addressing the dynamicity of the production environment.

-

Human–machine interfaces and machine-to-machine communications: Augmented reality (or virtual reality) will be used to support a number of tasks. Enhanced visualisation of data and analytic results will be required to support decision-making.

-

Human operators in more autonomous plants and in remote operations: the relationship between machines and the human factor needs to be rethought. In terms of the logic of human-machine interface, from touch displays, to wearable devices and augmented reality, but also to maintain the centrality of the human factor within the new contexts. The “Skills 4.0” are necessary for the management of new technologies for data administration, for privacy, for cybersecurity and much more.

-

Human safety: With the localisation of personnel, machines and vehicles, situation-aware safety (sensing of safety issues, proximity detection, online human risk evaluation, map generation, etc) will become increasingly vital.

-

Competence and quality of work in a human-centred manufacturing: At a strategic level, the European automation and industrial IT industry depends on its ability to attract skilled personnel to maintain their competence over time. A higher level of formal training may be required for workers in production and maintenance. Greater specialisation is constantly introducing products and processes that require greater company-specific training.

-

Green Deal: Policy initiatives aimed at putting Europe on track to reach net-zero global warming emissions by 2050 are key to the European Commission’s European Green Deal. Following the highly challenging objectives of the Green Deal, all industries must focus on high efficiency, low energy usage, carbon-neutrality or zero-carbon usage, zero waste from water, soil and air – all measured, calculated or estimated on product, factory, global and lifecycle levels. European industry must research and discover new materials while paying a great deal of attention to recycling, re-use, and de-manufacturing and re-manufacturing. As a “niche” and not exhaustive example new RICS-V based computing hardware will be needed to reduce energy used at data centres. Extra 3 x performance will be gained compared to ARM Cortex-A75.

Many of these advances will require extensive development in the other engineering, business or social domains, even at the individual level, that are outside of the Chips JU focus. However, it is also obviously the case that a growing part of these approaches will be implemented through the significant help of electronics and software technologies. The need for Chips JU technologies is diverse, and it is not useful to indicate one single technology here. High performance, high precision, careful and professional engineering and decision-making are needed – often at a much higher level than today.

3.3.4.3 Major Challenge 3: Artificial Intelligence in digital industry

Major challenge 3 focuses on connected and smarter cyber-physical systems (CPS), industrial internet, big data, machine learning, optimization, and other AI-based methods. Local edge-based intelligence is seen as an opportunity for Europe. AI optimized and Open hardware becoming more important to support European AI Framework. This Major challenge extends toward AI-enabled, adaptable, resilient factories, including the human as a part of a “socio-technical” system. AI methods, extending various systems used in modern industries, like(predictive) condition monitoring and maintenance, scheduling, planning, or quality control, will be applied to not only support reconfigurable first-time-right/zero-defect manufacturing, but also to support human decision-making (considering uncertainties). Consequently, AI-enhanced systems will enable resilient manufacturing ecosystems based on new business models, increase safety & security in working environments, and improve productiveness and quicker return from investments. In this context, Explainable AI (XAI) is another an emerging field for better understanding of decision making to increase human trust and robustness of emerging technologies. An important challenge here is to lead not only the digital transformation of Industry 4.0/5.0, but also the next generation of Chips JU platforms supporting AI-driven human-centric autonomous Industry 4.0/5.0 operations. Condition monitoring techniques can be applied to many types of industrial components and systems, although often at additional cost. Commonly, the business value required from condition monitoring depends on the higher availability of equipment and, for production processes, information provision to be able to plan and act on maintenance proactively instead of reactively, as well as to offer decreased cost and improved on-time delivery. Other business values that may be of interest are safety and the optimal dimensioning/distribution of spare parts and maintenance staff. Thus, serious breakdowns and unplanned interruptions to production processes can largely be avoided using condition monitoring.

AI will impact several main areas, all of which are relevant to Digital Industry improving:

-

Productivity, by exploiting AI in the design, manufacturing, production and deployment processes.

-

Flexibility, by using AI throughout the value stream, from supply to delivery, increasing the autonomy and resilience of each process in the value chain.

-

Customer experience, by using AI to make products faster and with better quality, and to provide more efficient services.

-

Assistance to human operators in circumstances of rising complexity by using AI to support the decision-making process with ever-increasing levels of complexity and dynamics.

-

AI radical innovations would enable more productivity and new products that just supporting, maintaining and improving existing ones

These fundamental impacts will be experienced in all areas of every market sector. In manufacturing and production, AI will deliver productivity gains through a more efficient resources, energy and material use, better design and manufacturing processes, and inside products and services, enhancing their operation with more refined contextual knowledge.

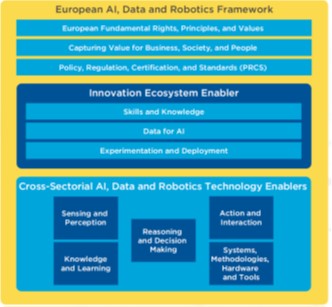

The agenda here is cross-sectorial, focusing on AI applied in any domain. However, the impact of AI in Digital Industry is of particular significance. AI in manufacturing is for example in one of the main focus of AI, Data and Robotics14 (ADR)and area of expected investments, already roadmapped by ADR since 202115

-

European AI framework

Figure 3.3.2 sets out the context for the operation of AI public/private partnerships (PPPs), as well as other PPPs or joint undertakings (JUs). It clusters the primary areas of importance for AI research, innovation and deployment into three overarching areas of interest. The European AI framework represents the legal and societal fabric that underpins the impact of AI on stakeholders and users of the products and services that businesses will provide. The AI innovation ecosystem enablers represent essential ingredients for effective innovation and deployment to take place. Finally, the cross-sectorial AI technology enablers represent the core technical competencies that are essential for the development of AI systems.

In June 2024 a big step forward has been made by the EU Parliament publishing the AI Act17, which is the first European regulation on Artificial Intelligence. Nevertheless ADRA (the AI, data and Robotics association) published in 2023 the "Strategic Orientation towards an AI, Data and Robotics Roadmap 2025-2027"18. Hence the European AI framework is still moving forward.

-

AI in manufacturing

-

AI for dynamic production planning and management: This involves taking real-time decisions to optimise the factory operation by quickly modifying the productions schedule, based on the current state of the shop floor, predicted sales orders, unexpected events such as machine breakdowns or changes in job priorities, etc.

-

Virtual models spanning all levels of the factory life and its lifecycle: A holistic and coherent virtual model of the factory and its production machinery will result from the contribution and integration of modelling, simulation and forecasting methods and tools that can strategically support manufacturing-related activities.

-

AI for green/sustainable manufacturing: The development of software-based decision-support systems, as well as energy and resource management, monitoring and planning systems, will lead to overall reduced energy consumption, more efficient utilisation and optimised energy sourcing.

-

AI applied in supply chain management: Planning and managing logistics for real-time operations, collaborative demand and supply planning, traceability, and execution, global state detection, time-to-event transformation, and discrete/continuous query processing would therefore be a challenge in view of the distributed nature of these elements.

-

AI for advanced manufacturing processes: The ability to design functionality through surface modifications, functional texturing and coatings, enabling improved performance, embedded sensing, adaptive control, self-healing, antibacterial, self-cleaning, ultra-low friction or self- assemblies, for example, using physical (additive manufacturing, laser or other jet technologies, 3D printing, micromachining or photon- based technologies, physical vapour deposition, PVD) or chemical approaches (chemical vapour deposition CVD, sol–gel processes) will deliver high functionality and hence high-value products.

-

AI for adaptive and smart manufacturing devices, components and machines: Embedded cognitive functions for supporting the use of machinery and robot systems in changing shop floor environments. Open Hardware based AI solutions will also support European AI Framework

-

AI for decision-making

Decision-making is at the heart of AI. Furthermore, Explainable AI will increase “human-centric” approaches in autonomous industry.

-

AI can support complex decision-making processes or help develop hybrid decision-making technologies for semi-autonomous systems.

-

Human decision-making, machine decision-making, mixed decision-making and decision support.

-

Sliding or variable decision-making, dealing with uncertainty.

-

AI for human interaction with machines.

-

AI for monitoring and control

-

AI for control technologies.

-

AI for monitoring services.

-

AI for maintenance systems for increased reliability of production systems.

-

AI services for continuous evaluation and mitigation of manufacturing risks.

-

AI for quality inspection.

3.3.4.4 Major Challenge 4: Industrial service business, lifecycles, remote operations and teleoperation

The volume and value of industrial services are increasing by between 5% and 10% every year. The share of services has exceeded the share of machinery for many machines, system and service vendors – not just for a final assembly factory, but also for companies in supply chains. Companies are willing to take larger shares of their customers’ businesses, initially as spare part suppliers, but increasingly for remote condition monitoring, as well as extending this to a number of those tasks previously considered as customer core businesses. From a customer point of view, such a shift in business models lies in the area of outsourcing.

Industry as services is changing the production through use of externalisation moving local tasks to external and ever more specialised providers, benefiting of greater flexibility, resilience and adaptability on production; a new proposition of supply chain is embedding all production phases, from the procurement of raw materials and semi-finished products up to the customer services and/or the design of parts or whole final product.

While many businesses have become global, some services are

still provided locally, at close to customer’s

locations, while other services are provided centrally by

the original vendor or companies specialised in such

services. Similarly, as there may be extensive supply chains

underpinning the vendor companies, the respective services

may also extend to supply chain companies. The industrial

era is becoming a service era, enabled by high-end Chips JU

technologies. This distributed setting conveniently fits

into modern edge-to-cloud continuum innovative architectures

as computing power engines and infrastructures enabling

emulation, training, machine learning and communication

platforms enabling real-time interconnections. ![]()

The importance of service businesses to the future is evident as they enable a revenue flow beyond traditional product sales, and more importantly they are typically much more profitable than the product sales itself.

The service business markets are becoming more and more challenging, while high income countries are focusing on the high-skilled pre-production and lifecycle stages. Fortunately, in the global service business market, Europe can differentiate by using its strengths: a highly skilled workforce, deep technology knowledge and proven information and communications technology (ICT) capabilities. However, to ensure success it needs new innovations and industry-level changes.

-

Remote operations, teleoperation

-

Remote engineering and operations, telepresence: Operating or assisting in operations of industrial systems from remote sites.

-

Edge/cloud solutions: Implementing distributed service applications on effective edge cloud systems.

-

5G with very low latency will be used for remote operations.

-

-

AI Services for monitoring and collaboration

-

Collaborative product-service engineering, lifecycle engineering: Extending R&D to take into account how products and systems will be integrated into the industrial service programme of the company. This should possibly be enhanced by obtaining further knowledge to provide services for other similar products (competitors!) as well their own installed base.

-

Training and simulation: Complex products such as aircrafts, drones, moving machines and any tele-operated machineries need a simulation environment for proper training of the human driver/operator.

-

Condition monitoring, condition-based maintenance, anomaly detection, performance monitoring, prediction, management: The traditional service business sector is still encountering major challenges in practice. It will therefore require an extension to the above, as targets of services are expanded to other topics in customer businesses in addition to spare parts or condition monitoring.

-

Strategic partnership and data capitalization, "data as currency", will be key factors that will enable new business model inside AI service business

-

-

Fleet management, Edge and local/global decision making

-

Decision and operations support: In most cases, decision-making is not automatic, whereas in the future it could be based on remote expert assistance or extensive diagnosing (AI-based, etc), engineering, and knowledge management systems.

-

Fleet management: This could benefit on the basis of sold items, by obtaining knowledge and experience from range of similar components and machines in similar or different conditions.

-

-

Business services integration

-

Local and global services: Organising services locally close to customers and centrally at vendors’ sites.

-

Full lifecycle tutoring: Monitoring activities, level of stress and performance-oriented behaviour during the product’s life, from anticipating its end of life to properly handling its waste and recycling, including improved re-design for the next generation of products.

-

3.3.4.5 Major Challenge 5: Digital twins, mixed or augmented reality, telepresence

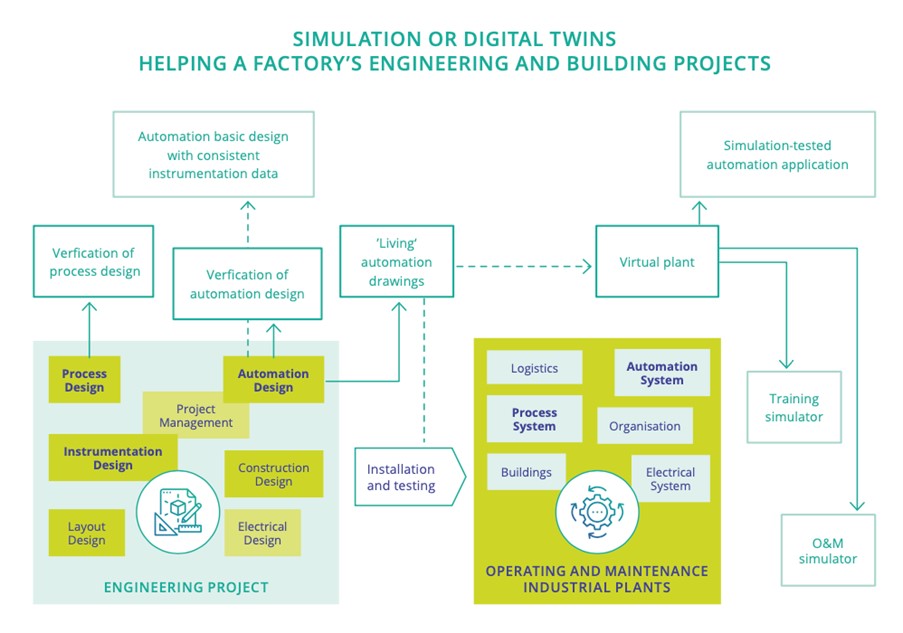

A “digital twin” is a dynamic digital representation of an industrial asset that enables companies to better understand and predict the performance and behaviour of their machines, and also to find new revenue streams. Currently, connectivity to the cloud allows an unprecedented potential for the large-scale implementation of digital twin technology for companies in various industries. A physical asset can have a virtual copy running in the digital twin environment, increasing revenue through continuous operational data. Similarly, several plants can operate in the same virtual space benefiting from globally shared data and remote automated decision-making. Factory/mill level digital twins are ever more autonomous and intelligent and can be adaptative by on-line learning. If needed they can interact to cloud level to evaluate model and optimize parameters using transfer learning at cloud.

Simulation capability is currently a key element in the European machine tool industry’s attempt to increase its competitiveness. In the Industry 4.0 paradigm, modelling plays a vital role in managing the increasing complexity of technological systems. A holistic engineering approach is therefore required to span the different technical disciplines and provide end-to-end engineering across the entire value chain.

In addition to virtual commissioning, modelling and simulation can more widely respond to many digitalisation challenges:

-

visualising physical or real-world phenomena of products, production, businesses, markets, etc.

-

helping designers to perform their core tasks – i.e., studying alternative designs, optimising solutions, ensuring safety, and providing testing for automation and Internet of Things (IoT) solutions.

-

The effects of changes can be safely and more comprehensively assessed in advance in a virtual domain rather than using real plants, equipment or even mock-ups.

-

Simulators offer versatile environments for users or operator training.

-

It is evident that former computer-aided design (CAD)-driven digitalisation is shifting the focus towards simulation-based design.

Simulators may be used online and in parallel with its real counterpart to predict future behaviour and performance, provide early warnings, outline alternative scenarios for decision-making, etc., although they have years of research behind them, such tracking simulators are to be co-designed and improved exploiting also recent investments in computing infrastructures (e.g. HPC EU families, EPI initiative), with a special focus on the industrial context.

Telepresence technologies can also be considered as the predecessor for an extended reality (XR) presence. The combination of new and advanced technology like e.g. XR, Artificial Intelligence of Internet of Things (AIoT), Edge, High Performance Computing (HPC), 5G and open integration platforms offers significant potential for innovation, which would benefit the evolution of European digital industry.

As an example, XR is a combination of virtual and augmented reality, and an XR presence is a continuum between a physical reality presence and a virtual reality presence. The main driver here is improving competitiveness through better productivity, more effective worker safety and better quality. The industrial applications have followed the prospects offered by the gaming industry and consumer applications. One of the reasons for its increased take-up is the declining cost of electronic components and sensors.

As some major smart glass producers will provide technology and a platform for consumers, other EU industrial groups could do the same, and the EU industrial ecosystem could take benefit of such devices and provide industrial use cases. These can be extended then to state-of-art applications. “Back-end” services are Digital Twins and Condition Monitoring systems that will provide everything that optimizes the system work, providing critical and useful information for the Field Worker. Longer vision for the integration human actions and back-end data servers can be used to build knowledge graphs to help other users to work like experts. As a summary: smart glasses can extend human understanding and knowledge if services and information flow can be utilized and formed to usable knowledge.

The EC "Data Act" initiative19 issued in 2024 promotes reliable and secure access to data within the European data economy and helps to advance the digital transformation by managing various aspects of data sharing, exchange and use. In terms of industrial applications and global interoperability between different legal entities, this means that data ownership and data use must be properly managed. For example, when digital twin processes data supplied by a tool manufacturer (data holder), then the user of this tool must be informed about this activity.

-

Digital Twin: Design process digitalisation, telepresence

-

Heterogeneity of systems: Information sharing and standards and means to ensure interoperability of digital twins and their information sources are important to facilitate information synchronisation. Having all relevant engineering disciplines (processes, assembly, electronics and electrical, information systems, etc.) evolving together and properly connected over the lifecycle phases is therefore crucial. This also involves multi-domain simulation, joint simulation of multi-simulation systems coupling.

-

Immersive telepresence for industrial robotics from design toward production lines and any other operational scope.

-

Digital twins applied to sustainability and circular economy: Simulate the usage of energy, use of raw material, waste production, etc., with the goal of improving energy efficiency and circular economy performance.

-

-

Virtual commissioning, interoperability:

-

Virtual commissioning: Digital twins applied to virtual commissioning to bring collaboration between different disciplines and models from domains of engineering (mechanic, electronic, automation) in the same environment.

-

Interoperability: Applications cannot yet be used across platforms without interoperability.

-

-

Simulators: Tracking & Simulator based design

-

Tracking mode simulation: Model adaption based on measurements. Generating simulators automatically from other design documentation, measurements, etc. Generation of simulators from 3D, data-driven models, etc.

-

Simulator-based design: Digital twin for testing the designed model by replacing the required physical components with their virtual models. This offers continuous design improvement (the digital twin provides feedback and knowledge gained from operational data), design optimisation, etc.

-

-

Digital twins combined with data-driven models (knowledge and data fusion):.

-

Combination of data-driven and knowledge-based models along the complete lifecycle (product and production). The real challenge is to combine physics and knowledge-based models (digital twins) with data- driven models (models created using AI from massive acquired experimental data), capitalising on the strength of information present in each of them.

-

New ways to generate large 3D scenes have been based, for example, on NeRF (Near Radial Field) and/or the Gaussian Splats.

-

-

Humans & Knowledge integration:

-

Human-in-the-loop simulations: Methods and simulations for human-in-the-loop simulations and integration of digital twins in learning systems for workers.

-

The 3D Internet platform: to integrate all of the aforementioned aspects into a single powerful networked simulation for humans to get the Situational Awareness for an industrial process as a whole.

-

Live 3D Digital Twins: to provide the state awareness (animation & color etc.) in AR/VR/XR.

-

3.3.4.6 Major Challenge 6: Autonomous systems, robotics

Machines are usually more precise and efficient than humans when carrying out repeatable tasks. Thus, replacing or aiding work processes susceptible to human errors, quality defects and safety issues with machines will have an impact on quality and redundant waste. The application of AI in robotics and the same robotics without AI extends the opportunity for automation of manual tasks, increasing the sustainability, safety & security of the production and its green transition. This will reduce the environmental impact -efficient reduction of the waste and optimise product quality toward zero-defect, process, and manpower. This will also achieve a more safe and secure working area to ease the human-machine, and machine-machine co-working.

There are many kinds of autonomous systems, (co)-robots and working machines. Just to give an insight into their widespread adoption, can be categorised by purpose, as follows:

-

Industrial machines and robots:

-

Manufacturing (e.g. welding, assembling, spray gun robots).

-

Material handling (e.g. conveyors, warehouse robots, trucks).

-

-

Consumer robots:

-

Domestic (e.g. robotic lawn mowers or vacuum cleaners).

-

Care (e.g. lifting or carrying robots).

-

-

Healthcare and medical robots:

-

Robotic surgery, hospital ward automation.

-

Medical tests and hospital care, remote healthcare.

-

Medical imaging, exoskeletons.

-

-

Moving machines:

-

Mining machines (e.g. drilling machines, dumpers, conveyors).

-

Forestry (e.g. forest harvester), agriculture (e.g. tractors, appliances).

-

Construction (e.g. excavators, road graders, building robots).

-

Logistics and sorting centres (e.g. cranes, straddle carriers, reachers, conveyor belts, sorting machines, trucks).

-

Military robots and machines.

-

-

Transport:

-

Vehicles, trucks and cars, trains, trams, buses, subways.

-

Aviation (e.g. aeroplanes, helicopters, unmanned aerial vehicles, UAVs).

-

Marine (e.g. vessels, ships, auto-piloted ships), submarine (e.g. auto-piloted submarines).

-

-

Utilities and critical infrastructures:

-

Extraction (e.g. drills for gas, oil).

-

Surveillance (e.g. quadcopters, drones).

-

Safety, security (e.g. infrared sensors, fire alarms, border guards).

-

Energy power plants sensors and actuators (e.g. production and distribution).

-

Transportation (e.g. moving bridges, rail exchanges).

-

The main aims and evolution trends of robots and autonomous systems in digital industry are oriented toward:

-

Production efficiency, speed and reduced costs,

-

Higher precision and quality, safety in working conditions,

-

To scale up “smart and high-end manufacturing”.

As is evident from the above, robots and machines and in particular autonomous systems are involved in all application chapters of this SRIA in addition to Digital Industry – i.e. Digital Society, Health and Wellbeing, Mobility, Energy, and Agrifood and Natural Resources- and are positively impacted by any improvement on both technological layers of the SRIA; foundational and cross-sectional technology.

There is undoubtedly a move to increase the level of automation and degree of digitalisation in industry, which will ultimately lead to fully autonomous systems.

However, between low and high technology manufacturing (two extremes: entirely manual and fully autonomous), there will always lie a large area of semi-autonomous equipment, units, machines, vehicles, lines, factories and sites that are worth keeping somewhat below 100% autonomous or digitised. The reasons for this include:

-

A fully autonomous solution may simply be (technically) near to impossible to design, implement and test.

-

If achievable, they may be too expensive to be realised.

-

A fully autonomous solution may be too complex, brittle, unstable, unsafe, etc.

-

A less-demanding semi-automatic solution may be easier to realise to a fully satisfactory level.

When the extent of automation and digitalisation are gradually, reasonably and professionally increased, often step by step, they may bring proportionally significant competitive advantages and savings that strengthen the position of digital industries overall. However, since the extent of automation and digitalisation remains well below 100%, any potential negative effects to employment are still either negligible or non-existent. On the contrary, the competitive advantages due to the adoption of robotics and autonomous system solutions increases the market positions of companies and, generally, enhances the need for more people in the respective businesses. An evolution of work organization and leadership may be required to enable the full potential of the digital industry.

-

Autonomous functions of systems:

Advances in Artificial Intelligence simplify the development of fully autonomous systems, which can fully automate work tasks in various application domains by increasingly reducing the need for human intervention and, at the same time, allowing to highlight additional innovative functions. A prominent example can be found in the automotive domain, where autonomous vehicles are expected to play a key role in the future of urban transportation systems. Such a challenge in a so complex scenario will promote significant advances in any autonomous functions of the many systems which are integral part of the Digital Industry ecosystem.

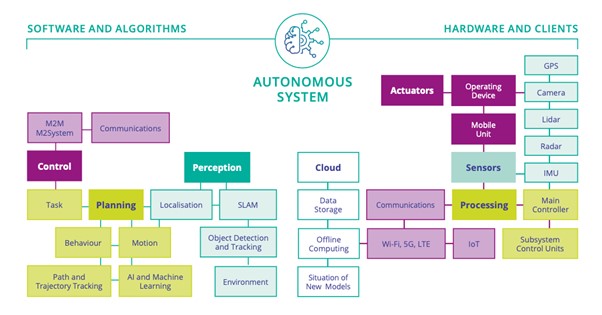

Autonomous robotics is the key enabling technology for the implementation of autonomously functioning shopfloors. Immediate benefits will be additional safety, increased productivity, greater accessibility, better efficiency, and positive impact on the environment. The following figure provides a generalised view of technologies and functionalities used in autonomous systems developed in the automotive domain. Nevertheless, this schematic representation of required building blocks can be generalized to many other types of autonomous systems.

The following figure shows matching of ISA95 standard that define control and other enterprise functions with building blocks of autonomous systems. The autonomy is expected to increase in the level 2 and Level 3 of ANSI/ISA9520.

-

Safety and security in autonomous systems:

Current standards of safety requirements for autonomous machines categorise safety into four approaches.

-

On-board sensors and safety systems for machines that work among humans and other machines but is restricted to indoor applications.

-

An isolated autonomous machine that works in a separated working area, mostly an intensive outdoor environment where other machines or humans are monitored.

-

Machine perception and forecast of expected and/or unexpected human activities aimed at: (i) assisting human activities and movements with a proactive behaviour; (ii) preserving human health and safety; and (iii) preserving the integrity of machinery.

-

An operator is responsible for reacting to a hazardous situation encountered by the autonomous machine when being provided with enough time between alert and transferring responsibility.

-

Requirements management and conceptual modelling of autonomous systems:

With the increasing complexity of autonomous functionality in both AV and ADAS systems, traditional methodologies of developing safety critical software are becoming inadequate. This observation can be made not only for autonomous driving, but in any industrial field of application of autonomous systems. Since autonomous systems are designed to operate in complicated real-world domains, they will be expected to handle and react appropriately a near endless variety of possible scenarios, meeting expectations from various stakeholders such as the internal engineering teams, people involved in the autonomous systems managements (e.g. passengers, drivers, workers, e-Health patients), regulatory authorities, and commercial autonomous vehicles/robots fleet operators.

-

Human–machine interaction in autonomous systems:

Improvements on sensing capabilities, on actuation control, IIoT (Industrial IoT) and SoS distributed capability are, in robotics and autonomous systems, the key enabler for:

-

Human-robot interaction or human-machine cooperation.

-

Transparency of operations between human and Advanced Machine Systems (AMS) in uncertain conditions.

-

Remote operation and advanced perception, AS oversight and tactical awareness.

-

Autonomy intended to enhance human capabilities.

-

Natural human interaction with autonomous systems.

-

Assisted, safety-oriented and proactive robot interaction with humans.

-

Digital design practices including digital verification and validation (V&V):

-

Automatic or semi-automatic V&V.

-

A digital design environment, digital twins, physical mock-ups.

-

Sub-task automation development, generation of training data and testing solutions and field data augmentation, according to a handful of global machine manufacturers.

-

Machine state estimation (assigning a value to an unknown system state variable based on measurements from that system).

-

Simulators and autonomous systems:

-

Process model based and product 3D-models approaches, environment and object models, and simulation tools.

-

Early design phase simulators.

-

Robotic test environments.

-

Empirical or semi-empirical simulators, making use of both real and simulated data collected from previous experiments.

-

Off-road environments.

-

Autonomous capabilities development in a digital environment

-

Autonomous decision taking.

-

Self-evolving capabilities.

-

Exploitation of knowledge in cognitive flexibility and in adaptability of the reaction.

The most obvious requirement for Digital Industry is the availability of all technologies, components and systems as described in other parts of this document both as foundation technologies and cross-sectorial areas serving and enabling the European Digital Industry mission.

It is extremely important that also a number of societal and policy needs are met, particularly the following aspects of EU legislation, related to working environments:

-

Adoption of trustworthy, responsible AI, XR and robotics.

-

To foresee exploitations of next generation HW architectures and new chip design (e.g. RISC-V, PIC).

-

Adoption of any type of technology safeguarding safety and security of workers.

Also the following aspects related to EU policies are to be taken into consideration, for the promotion of:

-

Resilience of EU production capabilities and supply chain towards Industrial EU sovereignty.

-

Sustainability of EU manufacturing renovation and evolution towards a greener and safer EU.

-

Digitalisation of EU Industry towards a quicker and better Innovation vocation, cost-efficient production, energy consumption saving and capacity to forecast market and societal needs.

| Major challenge | Topic | Short term (2025 – 2029) | Mid term (2030-2034) | Long term (2035 and beyond) | |

|---|---|---|---|---|---|

| Major challenge 1: Responsive and smart production | Topic 1.1: Robust optimal production, scalable first time-right production | manufacturing plants more robust able to ensure continue production by means of the reacting capability to external/ internal disturbance | large adoption of self-healing and redundant automation systems, and capability of first time-right, zero-defect manufacturing | predictive maintenance empowering a very adaptable production | |

| Topic 1.2: · Mass customization and personalized manufacturing, customer-driven manufacturing | shop floor optimization on base of increased data availability due to larger adoption of digitalization and secure communication | lot-size-one manufacturing and personalized product design | greater production flexibility, Mass customization and personalized manufacturing, customer-driven manufacturing | ||

| Topic 1.3: · Resilient and adaptive production, including the shortening of supply chains and modular and flexible factories | shortening of supply chains trend larger adoption of edge smart system/device in the shop floor | Adoption of even more modular and flexible lines/factories for a Resilient and adaptive production | Resilient and adaptive production | ||

| Topic 1.4: · Cognitive production |

larger integration of intelligent tools , cloud technology, embedded and remoted AI, complex analysis, big data, health monitoring of production equipment and products, IoT infrastructures for ever more “as services” approaches within the manufacturing process overall chain. |

Enabling new analytics and learning for responsive, sustainable and adaptive manufacturing involving natural and artificial cognition alongside IoT devices and data analytics | more cognitive production | ||

| Topic 1.5: · Manufacturing as a service | Any technologically advanced solution capable of enlarging the geographical distribution of production and strengthening the split and outsourcing of production phases within the manufacturing supply chain | More Manufacturing as a service, moveable factories, more resilient supply chain ecosystem | |||

| Topic 1.6: · · Embedded/Edge/Cloud architectures | larger adoption of 5G private networks nodes equipped with very powerful computing technology; Edge-to-Cloud and edge-to-edge communication and updating capability, embedded AI | Workload and services moved from the centralized data centres (core network) ever more to the proximity of production lines | |||

| Topic 1.7 · ·Standardization | continuous improvement of the integration and compatibility of the different standards in use | ||||

| Major challenge 2: Sustainable production | Topic 2.1: · Monitoring flows of energy, materials, waste and Lifecycle assessment | larger adoption of edge smart system/device and embedded AI in the production line | Sustainable production driven by those industrial sectors that need to fully track material and energy flows (food, medicine, etc.) | ||

| Topic 2.2: · Virtual AI assistants | Gen AI assistant and AI optimizer to help operators locally by providing advice based on LLM | Reducing the impact of human factor errors in the entire production chain (from design to production bay) | |||

| Topic 2.3: · Human–machine interfaces and machine-to-machine communications | Wearable and foldable devices; Gesture, eye and natural language command recognition, A&VR to become part of Advanced Human Machine Interface | Augmented reality; decision-making support by enhanced visualization of data and analytic results | Improved human-machine and machine to machine interfacing | ||

| Topic 2.4: · Human operators in more autonomous plants and in remote operations | development of robotic technologies (haptic, dexterity, active and return of force exoskeletons…) and system solutions for advancement on human machine cooperation and teleoperation in intuitive and safe manner | integration of Localization devices for indoor/outdoor navigation and position tracking | coordinated and distributed system solutions, able to ensure a smart and safe workspace where humans collaborate with machines using the strengths of both simultaneously | ||

| Topic 2.5: A· Human safety | localization of personnel, machines and vehicles, situation-aware safety | sensing of safety issues, proximity detection, online human risk evaluation, map generation, enabling an assistive control for co-working interaction | |||

| Topic 2.6: · Competence and quality of work in a human-centered manufacturing | ability to attract skilled personnel and to maintain their competence over time | ||||

| Topic 2.7: · Green deal | high efficiency, low energy usage, carbon-neutrality, or zero-carbon usage, zero waste from water, soil and air-measured, calculated or estimated on product, factory, global and lifecycle levels. | zero global warming emissions by 2050 Recycling, re-use, and de- and re-manufacturing | |||

| Major challenge 3: Artificial Intelligence in digital industry | Topic 3.1: European AI framework | Set out the context for the operation of AI public/private partnerships (PPPs), as well as other PPPs or joint undertakings (JUs). Define the primary areas of importance for AI research, innovation, and deployment. Consider and evaluate the impact of AI on stakeholders and users of the products and services by means of initiatives on AI. | |||

| Topic 3.2: AI in manufacturing | AI for dynamic production planning and

management Virtual models spanning all levels of the factory life and its lifecycle AI for green/sustainable manufacturing AI applied in supply chain management AI for advanced manufacturing processes AI for adaptive and smart manufacturing devices, components, and machines. |

Improving process integration at the shop-floor level to increase flexibility and dynamic production path on base of machine workloads, inventory, and production plans with a tightly coordination (vertical integration) with higher-level business processes such as procurement, quality control, marketing, sales, and distribution | |||

| Topic 3.3: AI for decision-makings | explainable AI to increase “human-centric” approaches in autonomous industry | AI to support complex decision-making (Human, machine, mixed decision-making) processes | |||

| Topic 3.4:AI for monitoring and control | AI for control technologies. AI for monitoring services. AI for maintenance systems for increased reliability of production systems. AI services for continuous evaluation and mitigation of manufacturing risks. AI for quality inspection. |

to exploit industry environment digitalization in an adaptive control to achieve smart horizontal integration (i.e. dynamic path of manufacturing through production stations on base of machine workload etc.) | |||

| Major challenge 4: Industrial service business, lifecycles, remote operations, and teleoperation. | Topic 4.1: · Remote operations, teleoperation | conventional industry infrastructures have to be adequate to protect from cyber threats and validated for new advanced applications ensuring continuous risk assessment and monitoring | Operating or assisting in operations of industrial

systems from remote sites. Implement distributed service applications on effective edge cloud systems. Large adoption of telecommunication network (5G) with very low latency for remote operations |

||

| Topic 4.2: · AI Services for monitoring and collaboration | Collaborative product-service engineering, lifecycle

engineering Training and simulation Condition monitoring, condition-based maintenance, anomaly detection, performance monitoring, prediction, management new business model inside AI service business based on data capitalization |

Exploit AI ability to recognize a strategy, an outline from highly variable patterns, in the definition of the state and maintenance of the machineries, in the optimization of the abstract models, in the identification and in the definition of new control strategies by means secure exchange of data | |||

| Topic 4.3: · Fleet management, Edge and local/global decision making | ever more unmanned vehicles\platforms, integrated in the factory layout to provide manufacturing needs and support production paths | Fleet management: Decision and operations support also based on

remote expert assistance capitalize in services knowledge and experience from range of similar components and machines in similar or different conditions |

enable an assistive control for co-working interaction improve customer remote assistance | ||

| Topic 4.4: ·Business services integration | Exploit the interoperability between different production frameworks and other engineering tools in the field of production planning and modelling | Ai support on organizing services locally close to customers and

centrally at vendors’ sites. AI support on full lifecycle tutoring |

to improve customer services and technical support, and to make customer active in product definition and delivery | ||

| Major challenge 5: Digital twins, mixed or augmented reality, telepresence | Topic 5.1: · Digital Twin: Design process digitalisation, telepresence | Thing Description as abstraction of physical entities for advanced interactions exploiting virtualization potentialities | Immersive telepresence for industrial robotics from

design toward production lines and any other operational scope. Digital twins applied to sustainability and circular economy Ensure interoperability of digital twins among systems' Heterogeneity |

||

| Topic 5.2: Virtual commissioning, interoperability | strength collaboration of different functional teams on the same common objective/business model | virtual commissioning to bring collaboration between different engineering domains on same environment. Platforms interoperability | |||

| Topic 5.3: Simulators: Tracking & Simulator based design | Model adaption based on measurements. Generating

simulators automatically from other design documentation, measurement Digital twin for testing the designed model by replacing the required physical components with their virtual models |

to support the design and development of completely new plants or new production in an existing plant | |||

| Topic 5.4: Digital twins combined with data-driven models (knowledge and data fusion | combine physics and knowledge-based models (digital

twins) with data- driven models (models created using AI), capitalizing on

the strength of information present in each of them New ways to generate large 3D scenes |

||||

| Topic 5.5:· Humans & Knowledge integration | Human-in-the-loop simulations: The 3D Internet platform Live 3D Digital Twins: to provide the state awareness in AR/VR/XR |

Allow a collaborative workspace, coordinated and distributed system solutions able to ensure a smart and safe workspace where humans collaborate with machines using the strengths of both simultaneously | |||

| Major challenge 6: Autonomous systems, collaborative robotics | Topic 6.1: Autonomous functions of systems | Advancements in Artificial intelligence to easier

achieve fully autonomous systems solutions human intervention reduction, introduction of additional innovative functions Autonomous robots enabling implementation of autonomous functions shopfloors Advancement on energy autonomous node (energy harvesting in sensors actuation ) |

Self-learning and control systems in increasing advanced

functionalities and smartness and awareness within the workspace Automated and innovative data-based services to reduce the offline measurement, increase fab automation reducing production cost and times |

||

| Topic 6.2: Safety and security in autonomous systems | Automated vision monitoring & Machine and robot vision in support to machine perception capabilities and to forecast of expected and/or unexpected human activities | assisting human activities and movements with a proactive

behavior; Preserving human health and safety; Preserving the integrity of machinery |

Collaborative workspace, coordinated and distributed system solutions able to ensure a smart and safe workspace where humans collaborate with machines using the strengths of both simultaneously | ||

| Topic 6.3: Requirements management and conceptual modelling of autonomous systems | involvement in autonomous systems definition of the expectations from various stakeholders such as the internal engineering teams, people involved in the autonomous systems managements (e.g. passengers, drivers, workers, e-Health patients), regulatory authorities, and commercial autonomous vehicles/robots fleet operators. | Increased complexity of autonomous functionality autonomous systems able to handle and react appropriately a near endless variety of possible scenarios | |||

| Topic 6.4: Human–machine interaction in autonomous systems | worker’s safety coordination by security of data exchange and low latency communication Improvements on sensing capabilities, on actuation control, IIoT and SoS distributed capability | Human-robot interaction (HRI): supporting the development of robotic technologies (haptic, dexterity, active and return of force exoskeletons…) and system solutions for advancement on human machine cooperation and teleoperation in intuitive and safe manner. Also support the intuitive programming of robots (e.g. voice/gesture control) | |||

| Topic 6.5:Digital design practices including digital verification and validation (V&V) | Process improvements based on shared information allowing

interaction in the value chain from product design up to deliver; Automatic or semi-automatic V&V. A digital design environment, digital twins, physical mock-ups. |

Sub-task automation development, generation of training data and

testing solutions and field data augmentation, according to a handful of

global machine manufacturers. Machine state estimation |

Supporting design of product and process development in manufacturing phases providing a fast settling of production lines and to improve batch production and Lot size”1 capability” and mass customization | ||

| Topic 6.6: Simulators and autonomous systems | to support the design and development of completely new plants or new production in an existing plant by simulation on virtual plant to better prepare physical production and verify product-production constraints | Process model based and product 3D-models approaches,

environment and object models, and simulation tools. Early design phase simulators. Robotic test environments. |

Empirical or semi-empirical simulators, making use of both real

and simulated data collected from previous experiments. Off-road environments |

||

| Topic 6.7: Autonomous capabilities development in a digital environment | Distributed processing capability on base of the robustness of communication and low latency on answer | Autonomous decision taking. Self-evolving capabilities. Exploitation of knowledge in cognitive flexibility and in adaptability of the reaction. |

|||